|

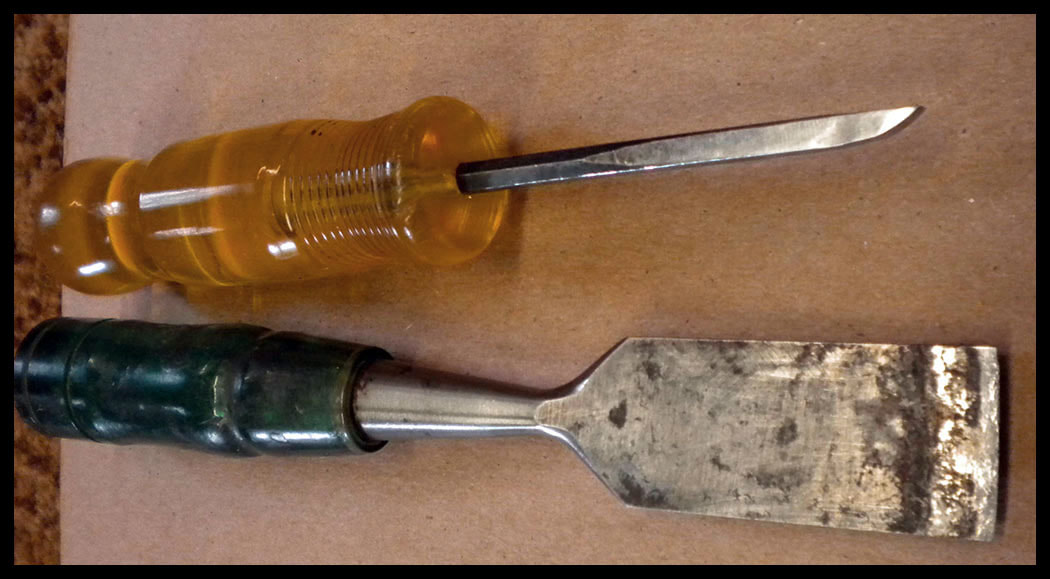

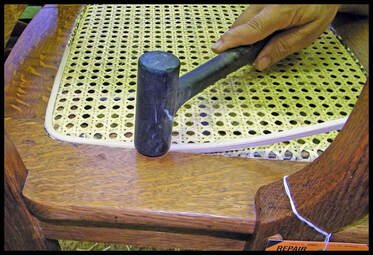

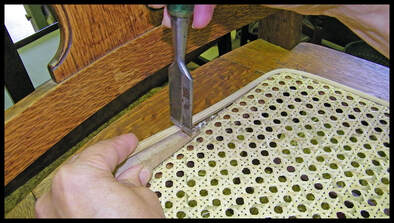

Use the tools recommended in the photo below to clean the groove.

|

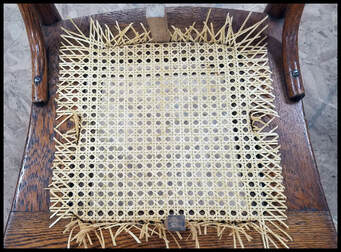

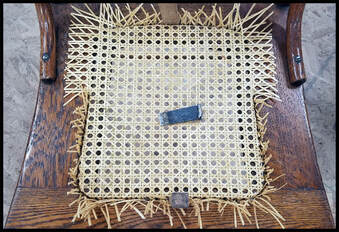

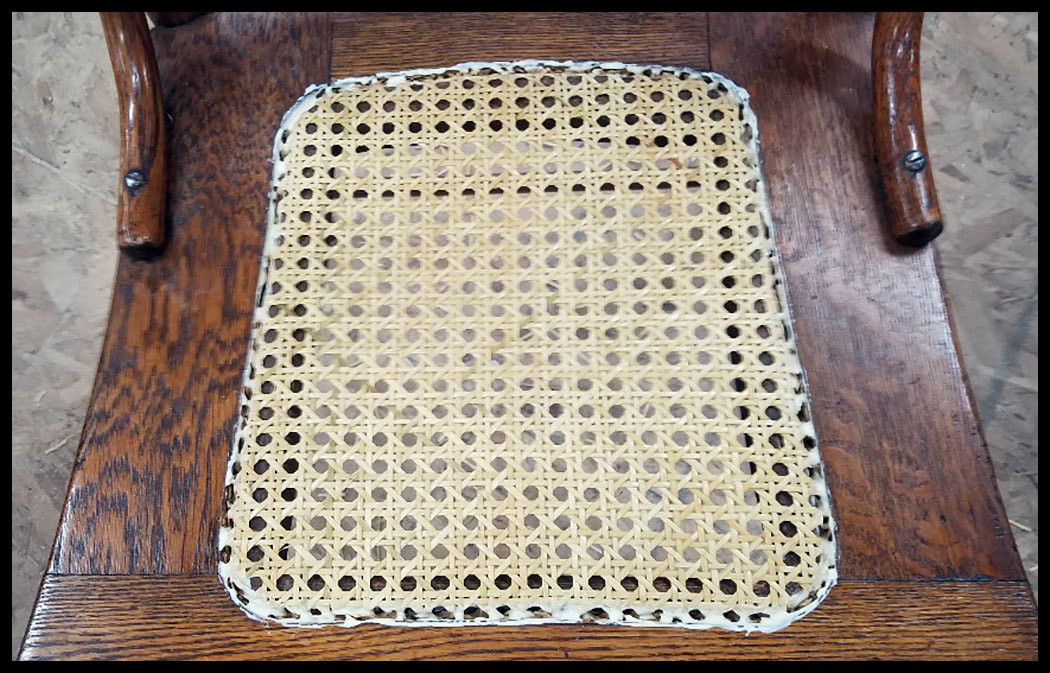

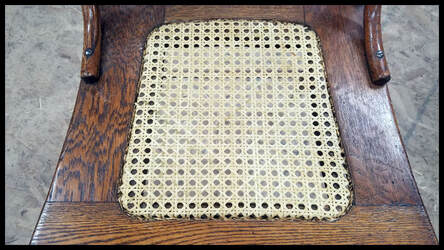

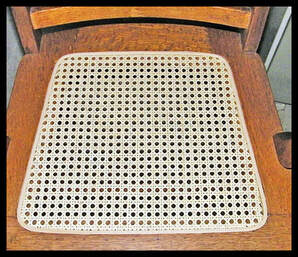

The photo above to the left is showing the cleaned out groove of the seat the cane and spline will be pressed into. Take your time during the removal process making sure you don't damage the outer flat of the seat face or injure yourself. There isn't much you can do to repair damage to the outer edge of the groove. Damage to the inner edge won't matter too much because the press cane will be hiding it. If the last person installing the seat used a waterproof glue it is going to be difficult to get the groove really clean. So be careful.

|

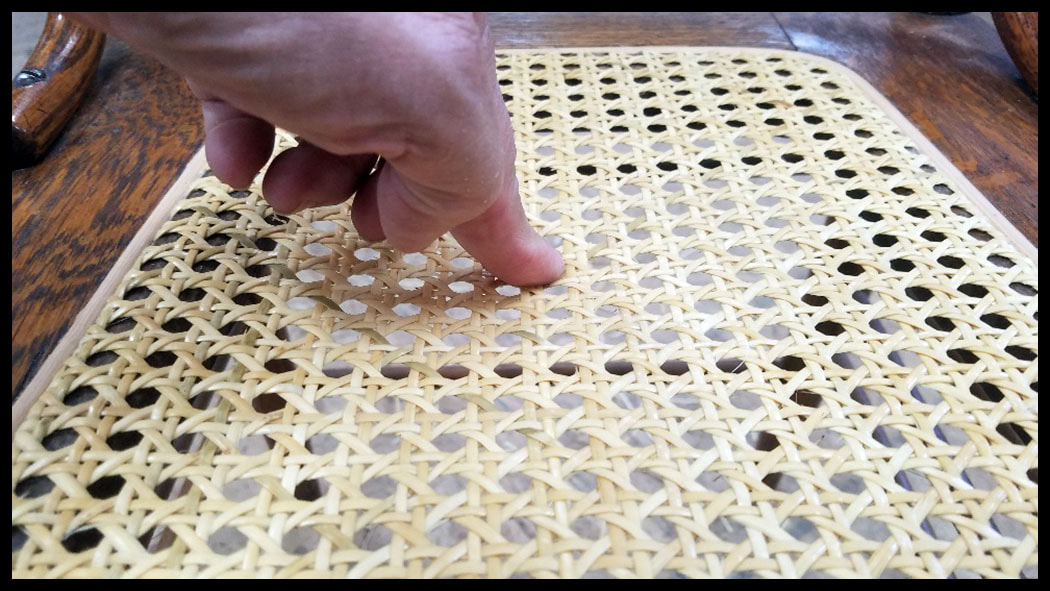

This page contains a series of photos on how to install 'Pressed (pre-woven) Cane'. There are are also books available online to help you that may be more detailed than I'm giving you here. Buy or order your pressed cane and spline before you remove the old seat, if the old seat exists. I say that knowing it can be a catch-22 circumstance for a novice, i.e. if you don't have experience in buying the materials. You will want to replace the cane and the spline with the same sizes they were to begin with. If the previous spline that was used was too small the seat may not have lasted very long to begin with. So it is important to measure the size of the pressed cane material and the spline. If you are starting with a chair that has already been stripped of its cane it means you have to some decisions to make on what size to use. There are plenty of sizes of pressed cane to choose from. Size, meaning how large the holes are in the woven cane you are going to buy. There are plenty of sizes to choose from. You then have to determine the hole size with in the woven material is the first you will want to determine. Then the size of the spline before you can order your materials.

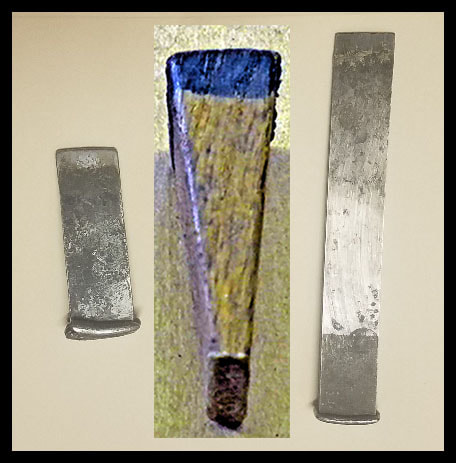

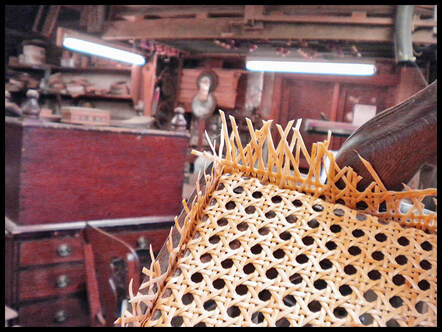

Some of you may find the expense re-caning your chair to be high because of the cost of materials, especially if you plan on caning only one seat. Most suppliers of caning material do business with professionals. If you plan on installing cane on a number of seats or seat backs you might try buying in bulk and save a little money over the long haul. Splines can be frustrating to buy because they range in close graduations of sizes and they can't be too big or too small. See photo of spline ends below.

For a short video on how to install cane in a chair seat, skip to the video file below

Remove the old pressed cane seat making sure the groove is completely free of glue. Take your time and do it right, any debris (old glue or pieces of it stuck in the groove will definitely cause a problem for you when you start installing the new cane. On another note, if you have a chair with holes and no groove it is not a candidate for pressed cane. Although If you wish, your chair can modified and I will give you some suggestions on how to convert it to having a groove at the end of this page. (future)

Installing a cane seat correctly will give you a great deal of satisfaction and you can proudly tell folks you did it yourself. Caution...One last thing before you start the caning process, look your furniture over carefully to see if any joints need gluing and/or parts need repair. There is no sense in spending your time and money to cane a piece of furniture in need of repair or refinishing. Check around, for cane pricing, which varies considerable depending the amount want to buy. I'm buying elsewhere because I buy in bulk making prices cheaper. The sizes of press cane are measured from center of hole to center of hole. They run from 3/8, 7/16, 1/2, 9/16, 5/8, 3/4 and 1” The larger the weave the larger the strands of cane in the weave. This is the standard cane weave with the octagon holes. The most common size used is 1/2" and shown in our example. There are other patterns of press cane weave available and some of them are too delicate to use in a seat. They are used for the backs of chairs or decorative projects. The size of the spline comes in different sizes starting at 5/64 to 5/16 in graduations of 1/64 of an inch. There are companies that sell online and will send samples of their material.

Two companies https://www.franksupply.com/ and https://hhperkins.com are set up for dealing with small quantities, But shop around.

Two companies https://www.franksupply.com/ and https://hhperkins.com are set up for dealing with small quantities, But shop around.

After cleaning out the groove, measure for the size of the spline using various sizes of spline. This means buying a number of samples if possible. Notice from the photo that the ends are slightly wedge shaped. Obviously, You want the thickest width (the top) of the spline to fit 'slightly' snug (wouldn't fall out if tipped upside down) in the dry groove (without cane in it). If you did pre-purchase the spline use this step to check to see if the size you chose is correct. And yes, that pressed cane has to go in there too. It's not called pressed cane for nothing. With the correct sizes your wet cane and wet spline will pound into the grove easily, although nice and tight when you get to that step. I included a larger photo of the spline ends to show, not only, some different sizes, but also the porosity of the spline. It is this porosity that allows the necessary compression on the spline to hold the seat in place against the sides of the groove. This helps you see the importance of using the correct size spline.