The photos shown on this page are on going small samples of the thousands of repairs (both big and small) we have accomplished in the forty four plus years I have been in business. It is only in the last few years that I started taking photos for placement on my website to show folks how many seemingly throw away pieces of furniture can not only be saved, but often made to look almost new.

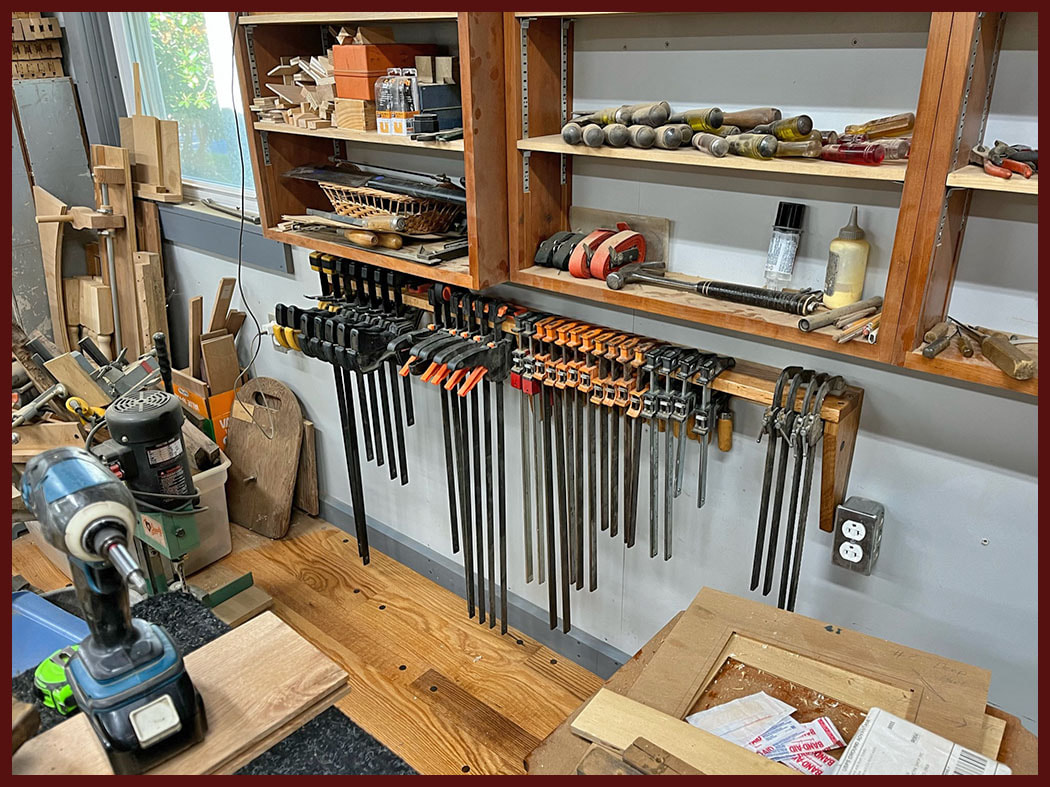

Now that my workshop building is mostly refurbished I need to make more storage available for my equipment/tools. Can't have too many clamps, especially with multiple projects taking place at the same time.

The owner of the green chair above right is one of a set of six dining room chairs. However, one of the chairs was badly damaged and beyond repair. He asked if I could recreate it so that he could have a full set. He will paint it. No problem! (Timeframe, Fall of 2023)

A customer brought in the top of an old workbench that she wanted cleaned up and sealed to protect it and give it a bit of a sheen. She already has legs for it that she will re-attach when she gets it home.

The above 5 images show a refurb of a lawyer's old file cabinet. Aptly identified as a Law Blank Cabinet for storing blank forms of various legal documents. The lower right image shows where eighteen newly made drawers (top right) fit into the cabinet. Think for a moment about the fact that a present day lawyer only has to log on to his or her computer, fill out a 'blank' form, print it out and apply the appropriate information and signatures. Then scan it back into the client's file and it's stored electronically. If that isn't saving wood, what is? 😎 Have a great day!

Two matching chairs came in, in pretty bad shape. I had to do some disassembly, repair broken pieces, reassemble, and refinish. The photos below are taken of the chair in the worse shape. The bottom photo is of both semi-finished chairs which are in line to be caned.

The photos grouped below are of a repair of an antique Stroller, High-Chair, and Rocker. These types of chairs were mad between. 1860 and 1910. The arms were uneven and one was broken. I laminated thin sheets of oak and glued them together, setting them in a pre-made form to clamp them together to form the shape of the arm. Once dry I cut the glued arm in half, giving me to exact arms. I believe the photos tell the story.

Ya gotta keep your tools sharp

This is an old (very) hand turned grinding wheel for sharpening knives and scissors. A customer found it recently in some yard sale and it needed a new handle, which you can see in the photos below. The wheel is about 8" in diameter and 2" thick. The rotating loop is about 12".

Certainly, it is a piece of history and will spark the memory of some old timers who will get a look at it. 🥸

Certainly, it is a piece of history and will spark the memory of some old timers who will get a look at it. 🥸

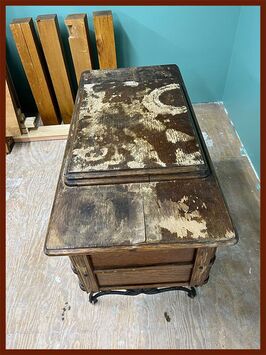

This drop-leaf table was repaired in January of 2022

The drop-leaf table below was probably built sometime in the 1800’s. Over time, it slowly deteriorated to the point of becoming unusable and the owner came to me to have it refurbished. That included replacing the top and the drop-leaves for one was badly scarred and the other was missing.

These photos show both before and after.

These photos show both before and after.

|

|

Project completed Dec, 2021

You're looking at an antique platform rocker (rocking mechanism removed for caning) that is roughly 100 years old, or older. It has been in the owners family for quite some time having belonged to the owner's grandmother.

The seat and back were upholstered when it was made and the rocker framework was renewed by removing a few coats of paint and re-finishing it with polyurethane or varnish. My job was to prepare it for press cain. To do that I had to remove the seat and arms in order to route a 3/16" grove around the inner edge. Once that was completed I could press the cane into place. The press cain is defined as 'Fine'. I use this size to give the chair a refined look and minimize being able to look through it and seeing the inner structure of the chair. It is also a bit stronger. |