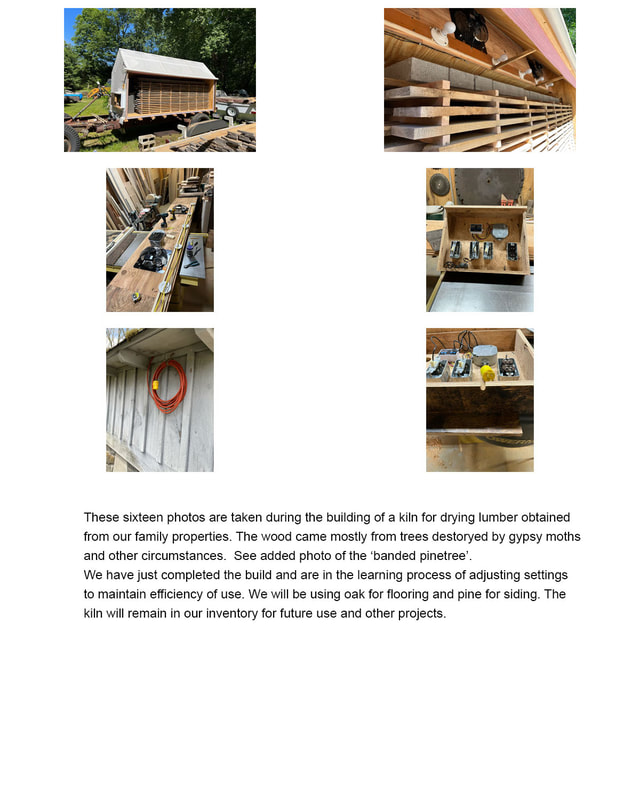

My brother Roland and I decided it worthwhile to build a kiln to dry the logs from the damaged trees we cut down more quickly. After dropping the trees, de-limbing the trunks and cutting them to eight feet in length to fit on Roland's portable bandsaw, the next step was to get the moisture out of them. The logs aren't useful until the moisture within the logs has been removed to meet specific levels. Left by themselves to dry is called seasoning. Obviously not a fast process. By cutting the logs into planks and placing them in a Kiln greatly speeds up the process. I did the initial research to see what went into building a kiln and the small photos below show parts of the progress we made. This setup allowed us to remove the moisture to useable levels in about about a month. Moisture levels vary dependent on the planned use of the wood.

Recently we purchased some higher quality components that will allow us to build a more efficient and robust kiln. I'm not in a rush to build it with winter about to descend upon us. And we still have more work to do on the refurbishment of the workshop (mainly installing oak floors) and I continue to accept projects related to my business. We'll post progress as we progress on that build.

|

The pine tree next to Roland's property shown to right had started to split (reason unknown). Once noticed it became apparent that it could fall down in a big wind storm and the first thing to do was to clamp it together before the pending disaster took place.

Because it stood at the edge of the road running by Roland's house and property the power company was contacted to determine if was under their jurisdiction to remove it because of its proximity to the electrical lines also along the road. They did take responsibility for downing it and were pleased to have done so before a minor tragedy took place The logs cut from it were sawn into boards and planks which will be used in both Rolands projects and the Morgan's woodwork shop renewal. |